HomePRODUCTS VIBRATION

VIBRATION

Proven reliability

All vibration welding machines provided by Daeyoung Ultrasonic are used in the fields of leading companies around the world and their reliability has been proven.

Excellent quality

All vibration welding machines provided by Daeyoung Ultrasonic are designed and manufactured under uncompromising quality system.

Customization available

Daeyoung Ultrasonic vibration welding machine is based on standardized model equipped with a variety of options which satisfies customer requirements.

-

515e

An ultra-compact standard model optimized for welding various small industrial parts.

more -

615e/630e

Small standard models with excellent versatility and suitable for welding of various products of small to medium size.

more -

630L

The entire machine was designed upside down compared to conventional welder where lower part vibrates for applications requiring small brackets to vibrate such as package trays.

more -

715e/730e/740e

Medium-sized standard models widely used to weld various medium-sized automobile and home appliance parts.

more -

815e/820S

Large standard models with 210~250Hz frequency range, excellent for welding wider and taller parts.

more -

830e/930e/950e

Large standard models with 95~125 frequency range, wide range of expandability from large interior and exterior automobile parts to various industrial products.

more

Advantages

Excellent performance

Daeyoung Vibration Welding Machine is equipped with an IGBT type vibration AMP developed in-house to maximize performance, and has excellent performance that can be used by automatically tuning the resonant frequency suitable for welding products.

Various product lines-up

For welding products according to standards in various industrial fields, we have a lineup of various models with both expandability and versatility.

precise control

Daeyoung Vibration Welding Machine has the performance suitable for welding various small and precision industrial parts.

Convenient automatic function

Up to 80 sets of user-defined welding parameters can be stored, and 15 sets of welding jig settings can be recognized, which is convenient for wide product production

Excellent user experience

Daeyoung Vibration Welding machine adopts GUI (Graphical User Interface) concept optimized for user environment based on Korean, English, Chinese, etc., so it can be used easily and conveniently in any environment.

safe system

Designed and manufactured to ensure the safety of users by implementing a system that meets various safety standards such as ISO, CE, KS, etc.

Products with vibration welding

Vibration welding method

Vibration welding is an industrial technology that uses friction heat generated by vibration and pressurization of two thermoplastic resins to melt and combine products into one product.

Vibration welding can quickly join complex and various types of parts, and it is eco-friendly and economical as it does not require the input of auxiliary materials such as adhesives for bonding.

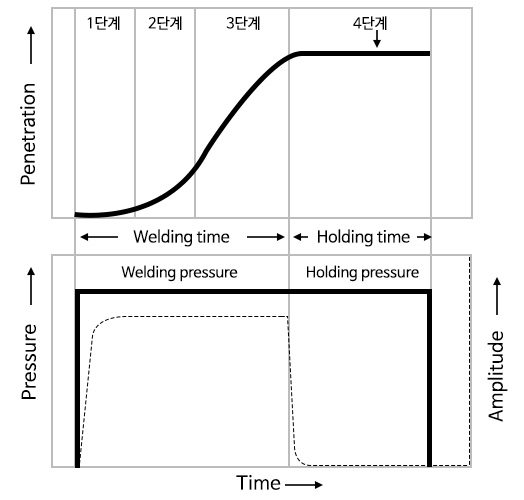

Step 1 - Friction in the solid state (melting start)

Step 2 - Form a molten layer in an unstable state

(The melt starts to come out)

Step 3 - Melt stable state, eluate consumption and molten layer formation are stable

(The amount of melt and the eluate are the same)

Step 4 - Stop vibration, and cooling (hardened in a welded state and product combination is complete)

Vibration welding technology

Servo control technology

The operation speed and position control precision of the worktable are improved by applying a high-performance precision servo motor, and high-quality products can be produced faster than the conventional hydraulic method.

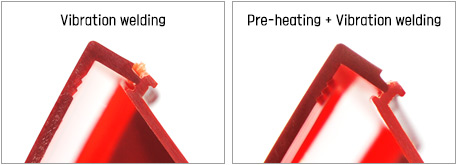

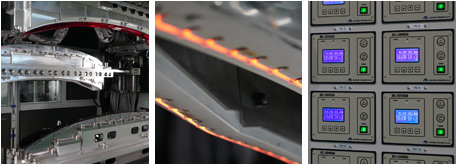

The pre-heating technology indirectly heats the welding surface through a hot coil before vibration welding, thereby reducing particulates generated on the welding surface during start of vibration friction, thereby producing cleaner products after welding. It can be applied to various products such as automobile lamps, intake manifolds and cylinder head covers that require cleaner end product

The preheating technology can quickly heat the welding surface through the high-performance preheating controller developed by Daeyoung. As it does not contact for heating, damage to the product and welding surface is minimized. Up to 12 preheating controllers can be added, and it can be applied to various products desired by customers through expansion.