HomePRODUCTS ULTRASONIC

ULTRASONIC

Customization available

Size, structure and function are designed and manufactured according to customer's requirements.

Excellent quality

All ultrasonic core components are managed under a thorough quality system with its own proven technology.

Abundant References

We provide customers with stable welding solutions with design technologies and various references obtained through continuous research and development.

-

Ultrasonic standard welding machine

Built-in amplifier type ultrasonic welding machine with compact size and sturdy structure.

more -

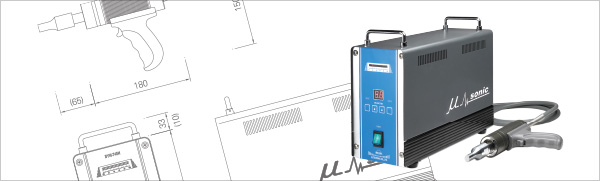

Ultrasonic handheld welding machine

Hand held ultrasonic welding machine with enhanced mobility and convenience.

more -

Ultrasonic multi-head welding machine

Customized ultrasonic welding machine that is flexibly designed and manufactured according to customers' requirements by applying modular ultrasonic head and amplifier.

more -

Ultrasonic Punching & Welding Machine

Customized ultrasonic punching and welding machine for sensor brackets on front & rear bumpers.

more

Advantages

Auto-tuning.

The ultrasonic welding machine provides optimal welding conditions by detecting the resonance frequency suitable for welding products through auto-tuning.

Diverse product lineup

Daeyoung Ultrasonic provides a diverse lineup of ultrasonic products suitable for the welding process of customer products.

Excellent reliability.

The ultrasonic welding machine designed for safe use by preventing malfunctions that may occur during use through reliable algorithms and safety functions.

Versatility & Increased Productivity

The ultrasonic welding machine is designed and manufactured to improve customer productivity by increasing versatility to be widely used in various plastic products.

Convenient user interface

The ultrasonic welding machine is designed and manufactured to provide a user-friendly and intuitive GUI (Graphical User Interface) environment, providing high user convenience.

Easy maintenance

The parts and components applied to the ultrasonic welding machine are modularized and designed and manufactured for easy maintenance.

Products with ultrasonic welding

Ultrasonic welding method

Ultrasonic welding is a suitable method for spot (staking) welding of thermoplastics. It uses the principle of precision bonding with frictional heat induced at the welding point by converting and transmitting the input electrical energy into ultrasonic vibration.

Ultrasonic welding is very effective in joining various fibers and vinyls, which are difficult to join by vibration welding and heat welding, without deformation or damage to the product, and the bonding quality is uniform and the welding time is short.

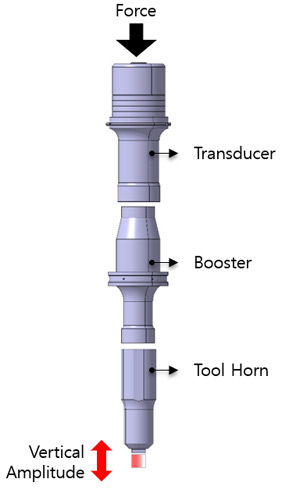

Structure of ultrasonic welding machine

Ultrasonic Amplifier: Ultrasonic Amplifier: Generates electrical energy from 15Khz to 50Khz and delivers it to the transducer.

Transducer:

Electrical energy received from the ultrasonic amplifier is converted to mechanical energy and delivered to the booster.

Booster:

It increases or decreases the vibration energy generated by the transducer according to the booster ratio.

Tool Horn:

It melts the welding surface of the product through heat (friction heat) generated by transmitting vibration to the welding surface of the product.

Ultrasonic welding technology

Ultrasonic amplifier design and manufacturing technology

Daeyoung Ultrasonic designs and manufactures high-performance, high-functional ultrasonic welding machine amplifiers in-house. We have a lineup of ultrasonic amplifiers for each application in handheld, standard and multi-head ultrasonic welding machine. We provide ultrasonic welding solutions suitable for various products.

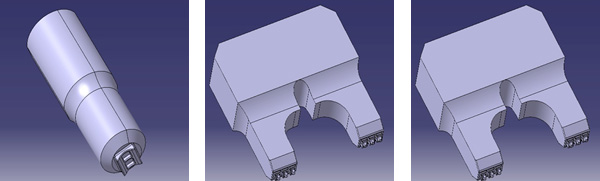

Jig and tool horn design technology

We design ultrasonic jigs and tool horns based on the technology accumulated through various projects over the years. The high level of jig and tool horn design technology prevents various problems that may occur during welding, dramatically reducing the product defect rate and producing superior quality products.