제품소개

HomePRODUCTS SPIN

SPIN

Specialized in welding round shaped products

The spin welding machine can be applied to the processing of various thermoplastic plastic products that are round in shape.

스탠다드

Specialized for round shaped products

By replacing the jig, it is possible to produce round shape products of various sizes.

High productivity

It provides high productivity with a very short process time compared to other welding methods.

Good airtight performance

Excellent welding strength ensures good airtightness.

SPECIFICATION

| Model | DSW-500AA | DSW-3000AH | DSW-6000AH | CUSTOM MADE |

|---|---|---|---|---|

| Product size | Up to 80 | 80~30 | 300~600 | Over 600 |

| Movement type | Head_ pneumatic | Table_Hydraulics | Table_Hydraulics | Table_Hydraulics |

| Head/Table stroke (mm) | 150 | 250 | 250 | Custom Made |

| Clamp maximum force (kgf) | 100 | 1500 | 2500 | Custom Made |

| Distance between head and table (mm) | 440 | 645 | 640 | Custom Made |

| Table size (mm) | 750 * 800 | 650 * 600 | 800 * 740 | Custom Made |

| Pneumatic parts | Festo | Festo | Festo | Festo |

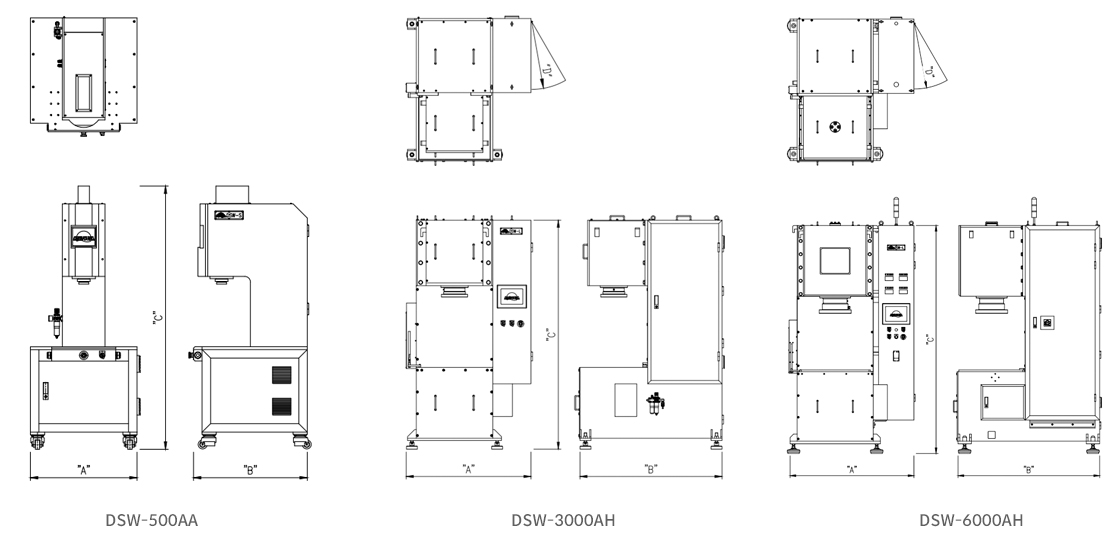

LAYOUT

| Model | DWS-500AA | DSW-3000AH | DSW-6000AH |

|---|---|---|---|

| A.Machine width (mm) | 750 | 1140 | 1400 |

| B.Machine depth (mm) | 800 | 1300 | 1600 |

| C.Machine hight (mm) | 1850 | 2100 | 2600 |

| D.Right door open (Control unit) (mm) | - | 620 | 740 |

Features

- - Accurate welding position and motion control are possible through the application of a linear sensor.

- - Easy to apply to semi-automatic or automated systems.

- - Through the touch panel, operator can monitor the operation status of the machine and easily set the welding parameters (melting length, line speed, melting time).

- - Welding parameters of up to 10 or more products can be saved.

- - Servo options available.

Applicable field

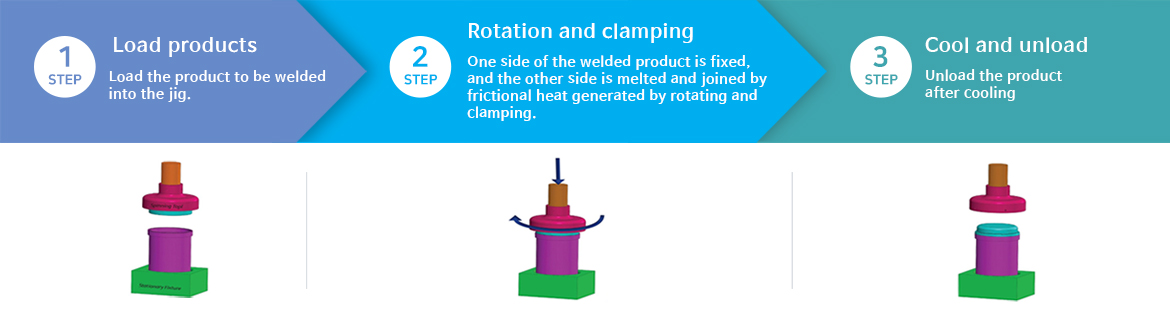

Spin welding method

- The spin welding machine fixes one of the parts to be welded, then rotates the other part at high speed then melts the welding surface through the rotary friction heat generated by pressurization.

- Products produced through spin welding have excellent welding strength and airtightness.