HomePRODUCTS OTHERS

OTHERS

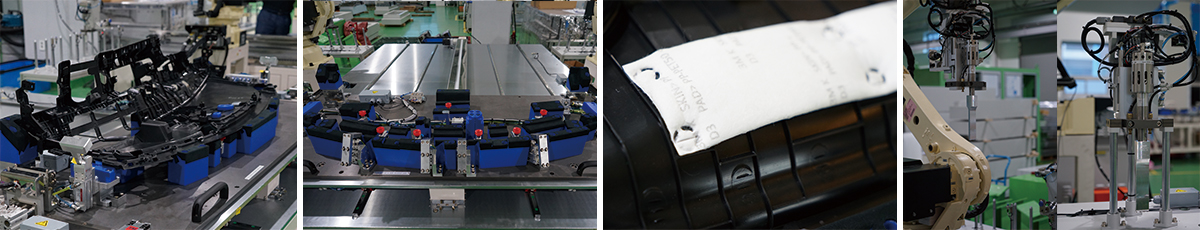

Daeyoung Ultrasonic provides an abundant automation solutions for plastic products

With combining Daeyoung Ultrasonic's plastic welding machine, an automated line can be composed which performs product supply, production, conveyor, and inspection process.

Advantages

Automation solutions

In addition to plastic welding machines, we have a diverse lineup of automation solutions to meet customer needs, such as assembly, conveyor, and inspection machines.

Customizations

The specification, structure and layout of the automation line are designed and manufactured according to the customer's request.

Daeyoung Ultrasonic provides a total solution from review-design-manufacturing-installation to commissioning of automation lines.

Abundant References

Automated lines produced with accumulated technology and abundant references provide customers with high-quality products and high productivity.

Other products

Leak tester

Inspects the airtightness of welded products.

- Fast and accurate inspection of welded products

- Custom design and production according to product shape and test requirement

- Can be connected to MES for process control

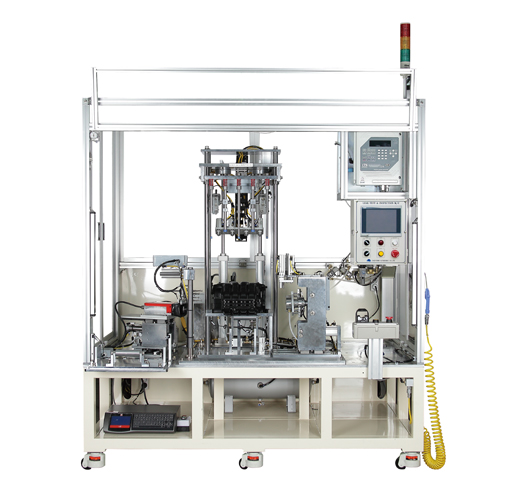

High frequency heat insert machine

Various nuts are heated with a high-frequency induction and inserted into the product

- Automate the nut supply-heating-assembly process

- Prevents discoloration of nuts from oxidation

- Suitable for multiple insertion process through robot application

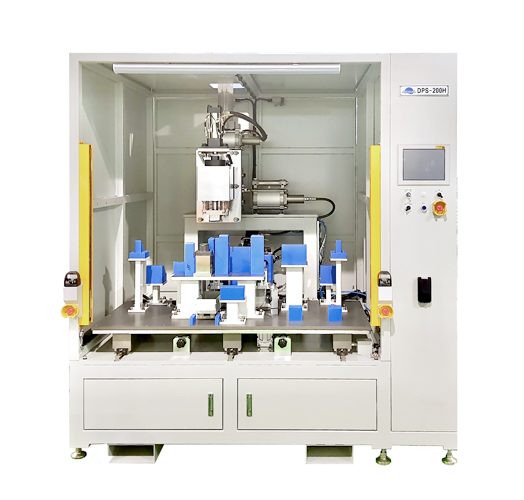

Hydraulic punching machine

The product is punched by the hydraulic cylinder.

- Applicable for parts requiring punching process such as sensor hole of automobile bumper

- Prevent part damage by making a jig according to the part shape

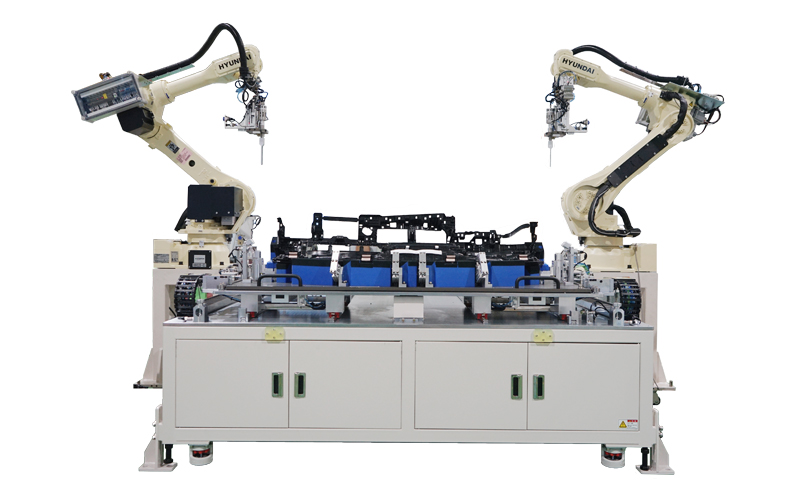

Ultrasonic welding machine (Robot and auto tool change system)

Ultrasonic welding machine with robot

By robot adaptation, it can weld multiple points effectively and the tool horn can be exchanged automatically.

It is suitable for small quantity batch production or prototyping.

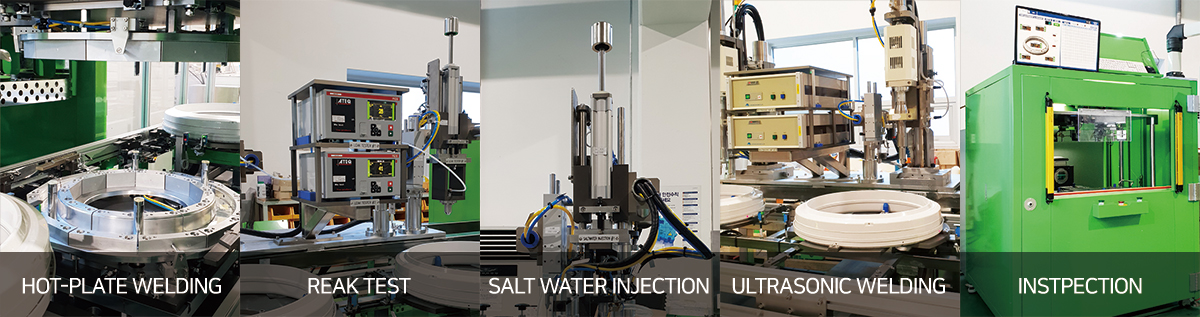

Washing machine balancer automated line

Automated line of the balancer manufacturing process from hot plate welding, to leak test, to salt water injection, to ultrasonic welding, to product inspection and marking.